Partnering with manufacturing innovators

Our customers eliminate production delays, reduce manual errors, and scale faster – all without adding headcount.

Optimize your entire manufacturing process with intelligent automation that adapts instantly to production changes, from demand planning to shop floor.

Our customers eliminate production delays, reduce manual errors, and scale faster – all without adding headcount.

Rigid ERPs struggle to meet manufacturing demands – batch changes require weeks of IT work, disconnected systems create data silos, and manual processes slow teams down. DOSS provides automated workflows that can be changed in minutes, connecting every aspect of production through composable modules that deliver results in weeks, not months.

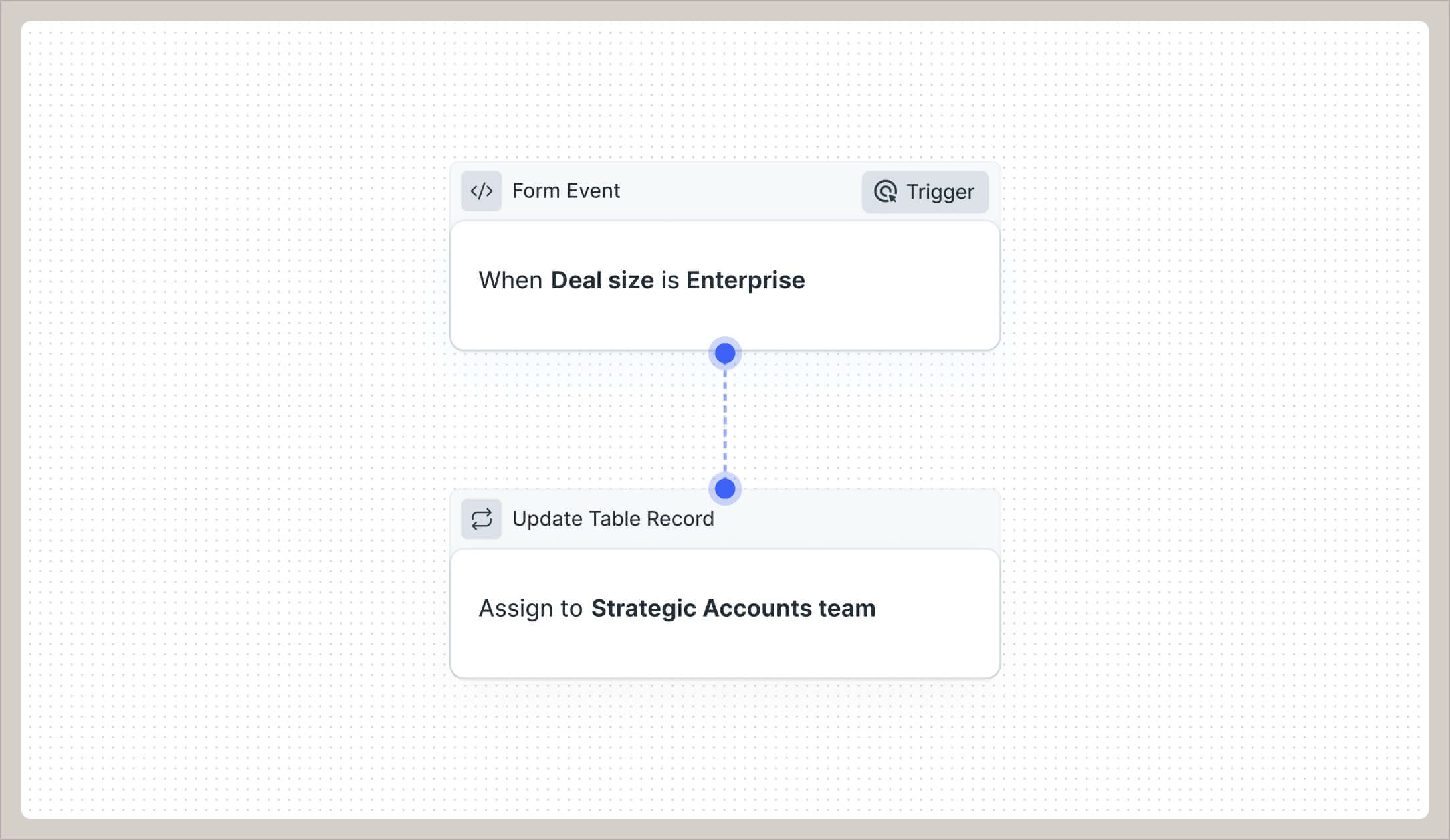

Eliminate manual handoffs and reduce production delays with workflows that automatically adapt to changing requirements.

Automatically route work orders by machine capacity, material availability, and priority rules

Dynamically optimize labor, equipment, and materials across production lines

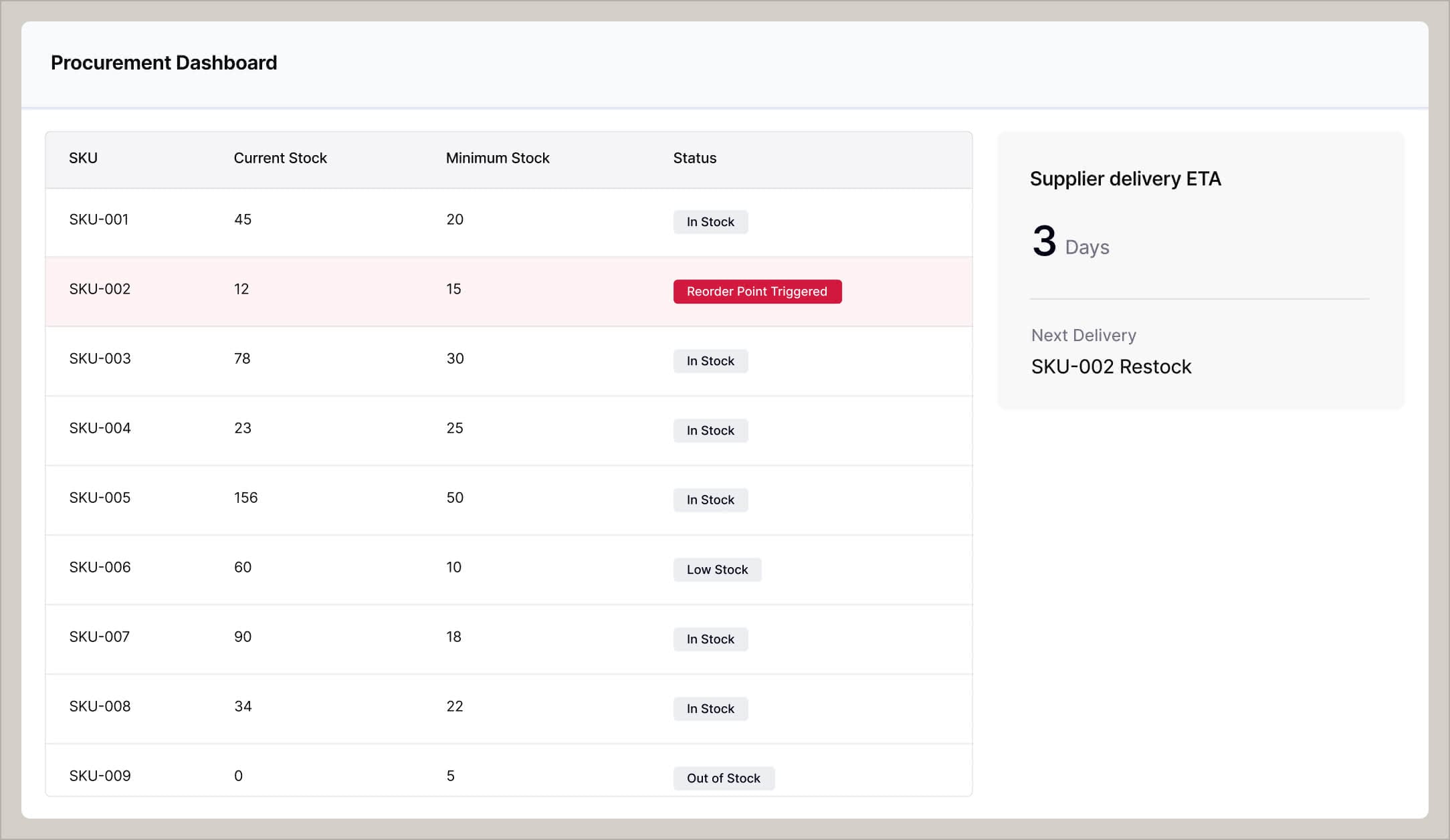

Get proactive alerts for quality issues, supply shortages, and schedule conflicts

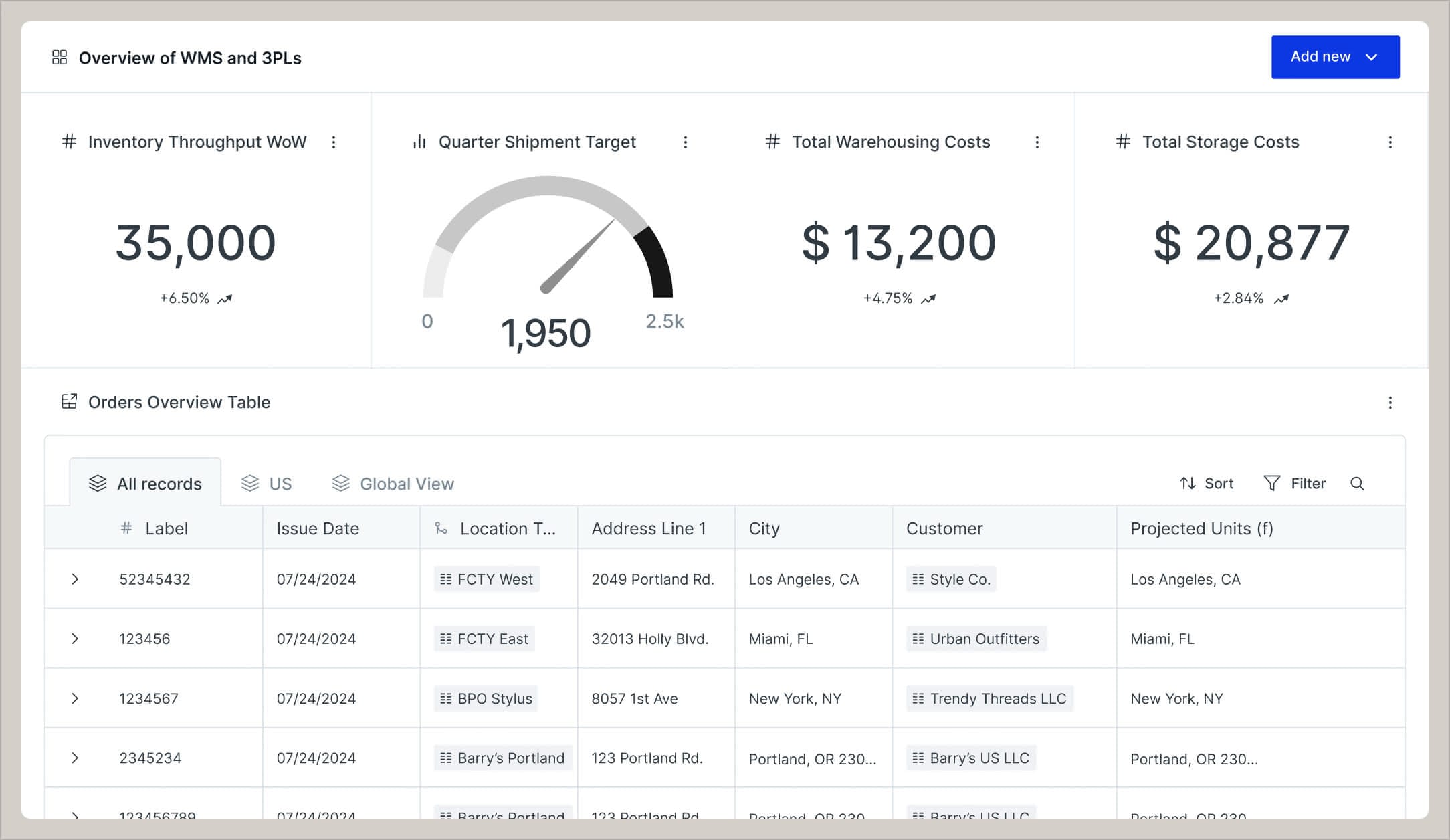

Build your perfect manufacturing system by connecting purpose-built modules that work together seamlessly with instant partner integrations.

Connect inventory, quality, scheduling, and planning modules without technical expertise

Get a single source of truth across all manufacturing operations with instant updates

Add new capabilities and locations in minutes without disrupting existing workflows

Spot bottlenecks, quality issues, and supply risks before they impact your bottom line with customizable formulas for predictive maintenance analytics.

Prevent machine failures and optimize maintenance windows with predictive scheduling and alerts

Detect quality drift with quality trend analysis and automated corrective action triggers

Featured modules and integrations for smarter manufacturing

As a platform, DossARP brings your data into one place. As a technology partner, we go a step further and make it work for you.

partner connections

days to implementation

hours saved monthly

ERP systems

Shop floor control systems

Quality management systems

Warehouse management systems

Yes. The DOSS demand planning module can combine historical data, predicted seasonality and more to generate accurate forecasts. DOSS ARP can automatically factor in lead times, safety stock, and production constraints to optimize your planning process and prevent stockouts.

Yes. DOSS can integrate with MES, PLCs, and shop floor equipment through standard protocols, or build them if there are developer docs available. Our platform enables real-time production monitoring, automated data collection, and seamless communication between planning and execution systems.

Our implementation team includes manufacturing veterans who understand industrial operations at scale. We provide dedicated project management, system configuration, data migration, user training, and 24/7 technical support. Most customers are live within a few weeks.

DOSS provides centralized control while maintaining facility-specific workflows. Balance production across sites, transfer materials efficiently, and maintain consistent quality standards. Each facility can operate independently while sharing a single source of truth for master data, giving complete visibility across your network.

Fast to deploy. Easy to change. Built to scale.