Production planning that adapts in real time

Transform complex demands into executable production schedules that maximize capacity, eliminate bottlenecks, and deliver on time. Master made-to-order workflows, unlimited scheduling, smart CPQ, and integrated BOM management without costly external tools.

Seamless multi-channel operations

3x faster

to fully deploy

(months, not years)

Unlimited

production schedules

(no extra cost)

Real-time

capacity planning

(with smart automation)

Master planning from raw materials to finished goods

Manufacturing teams struggle with production chaos — demand changes that scramble schedules, material shortages that halt production, and disconnected systems that create blind spots. DOSS delivers unified production control that connects every element, optimizing capacity utilization and eliminating delays through composable tables and automated, real-time workflows.

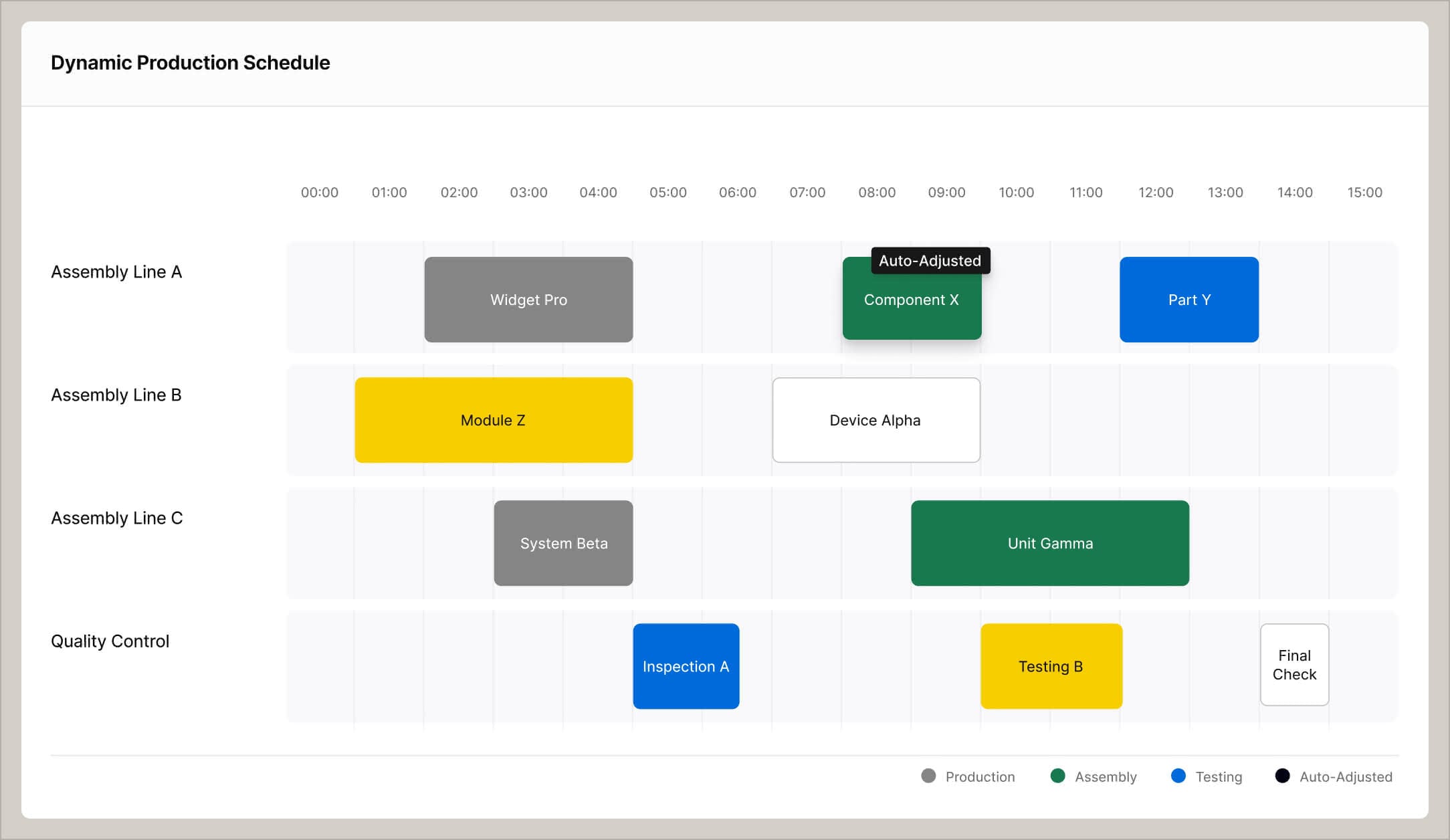

Create dynamic production schedules that adapt to demand

Build unlimited production schedules that automatically adjust to changing orders, material availability, and capacity constraints.

-

Create, store, and update unlimited production schedules in minutes without extra costs

-

Automate demand planning from production to sales with real-time schedule adjustments for material availability and order changes

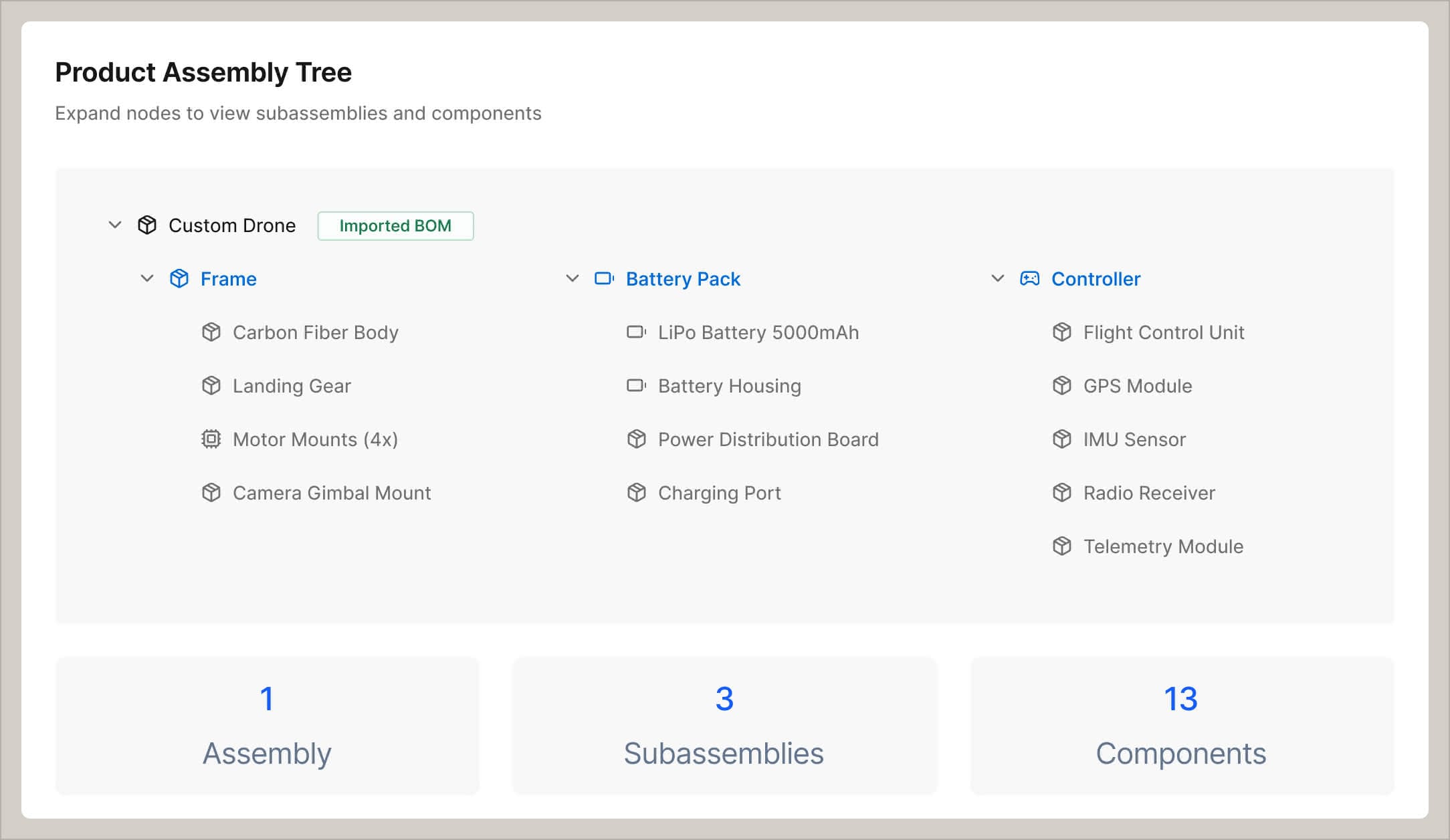

Streamline made-to-order and assemble-to-order workflows

Execute complex manufacturing operations efficiently at scale with automated, composable workflows that handle custom configurations, multi-level assemblies, and customer-specific requirements.

-

Automate made-to-order (MTO) and assemble-to-order (ATO) workflows

-

Customize production options for customer-specific and factory-specific needs

-

Import BOMs to streamline production planning

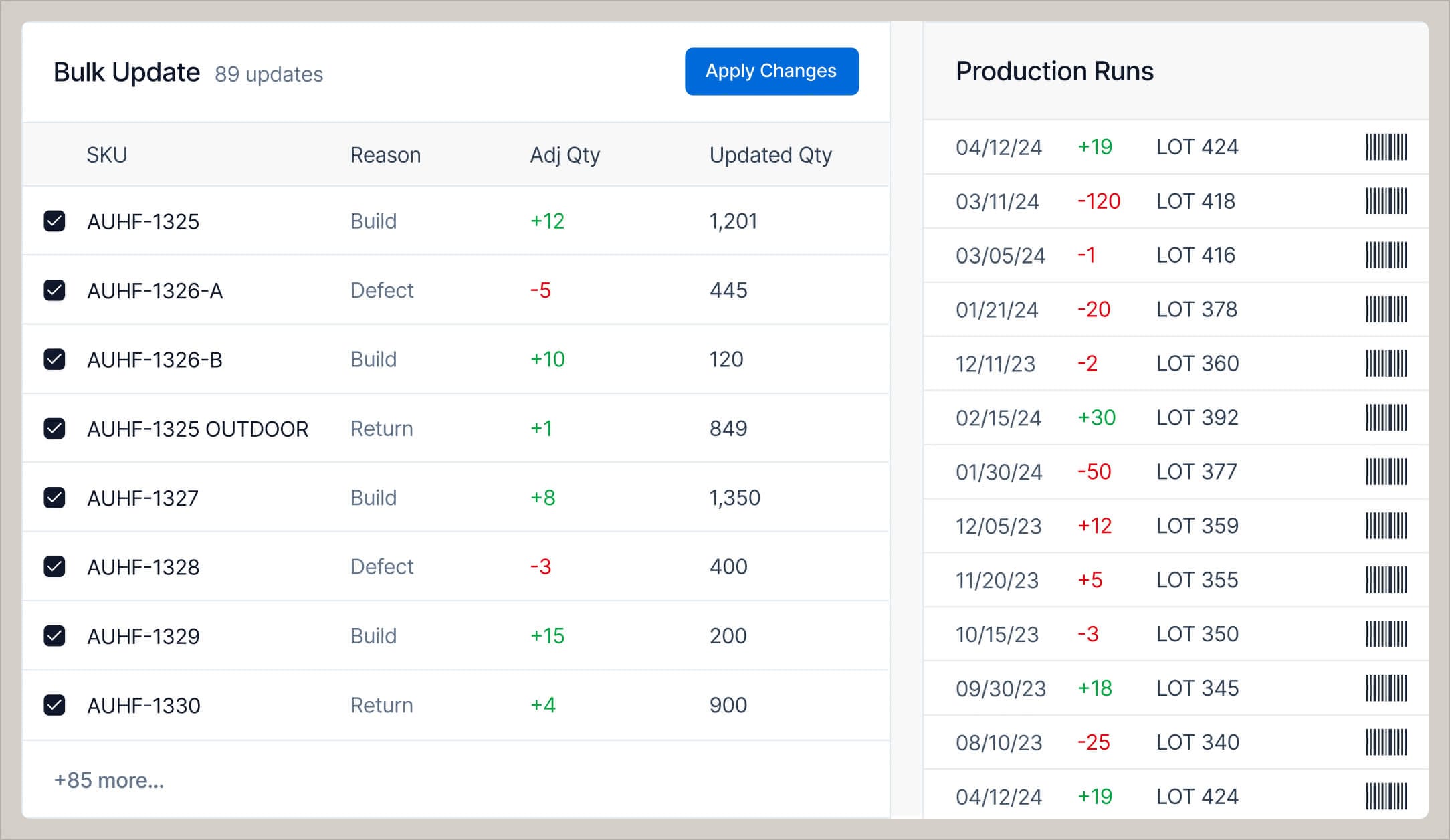

Connect production with procurement and inventory

Maintain perfect sync between production schedules, material requirements, and inventory levels. Eliminate production delays caused by material shortages or procurement timing mismatches.

-

See a comprehensive view of procurement, inventory, and production in one platform

-

Automate material requirements planning (MRP) based on production schedules

Frequently asked questions

Absolutely. With built-in BOM management and flexible configuration logic, DOSS supports multi-level assemblies, kit breakdowns, and dynamic CPQ workflows. Whether you're building custom hardware, furniture, or machinery, DOSS makes it easy to translate sales orders into precise, executable production plans.

Definitely. DOSS includes demand planning tools that pull from historical sales, open orders, and forecasted trends. You can compare expected demand to available capacity, visualize bottlenecks, and plan months ahead. It's perfect for manufacturers trying to scale operations without overcommitting or under-delivering.

DOSS uses live data from your inventory and sales demand to auto-generate material requirements, trigger POs, and schedule builds. Your master production schedule updates in real-time as orders come in, stock levels change, or supplier timelines shift — keeping you in sync from top floor to shop floor.

Yes. DOSS is built for multi-site production planning. You can assign work orders by plant, route them by resource availability, and track job progress with facility-specific views. If you're managing overseas factories, domestic assembly, or third-party co-manufacturers, DOSS gives you total control over where and how production happens.

DOSS gives you real-time visibility into key production metrics like schedule adherence, cycle times, material shortages, and order throughput. You can filter by product line, facility, or team — and use historical data to optimize future plans. It's production intelligence built into your daily workflow.

Yes. DOSS acts as a full-featured production planning and scheduling system, designed to eliminate spreadsheets and tribal knowledge. You can visualize capacity, reschedule on the fly, handle work orders, and align your MRP with actual demand — whether you run made-to-order, made-to-stock, or assemble-to-order operations.

Upgrade your ERP now

Fast to deploy. Easy to change. Built to scale.