Hitting $10 million in revenue is a milestone that changes everything about how a CPG brand operates. The scrappy systems that got you here (the spreadsheets, the manual reorder points, the Slack messages to your 3PL ) start to crack under the weight of real scale. New retail partners expect reliability. Your cash is increasingly tied up in inventory. And the decisions that used to be gut calls now carry six-figure consequences.

This is the stage where operational discipline separates brands that plateau from brands that reach $50M and beyond. Below is a practical checklist of the operational foundations every CPG brand should have in place at the $10M mark, organized around the areas where growing brands most commonly feel the pain.

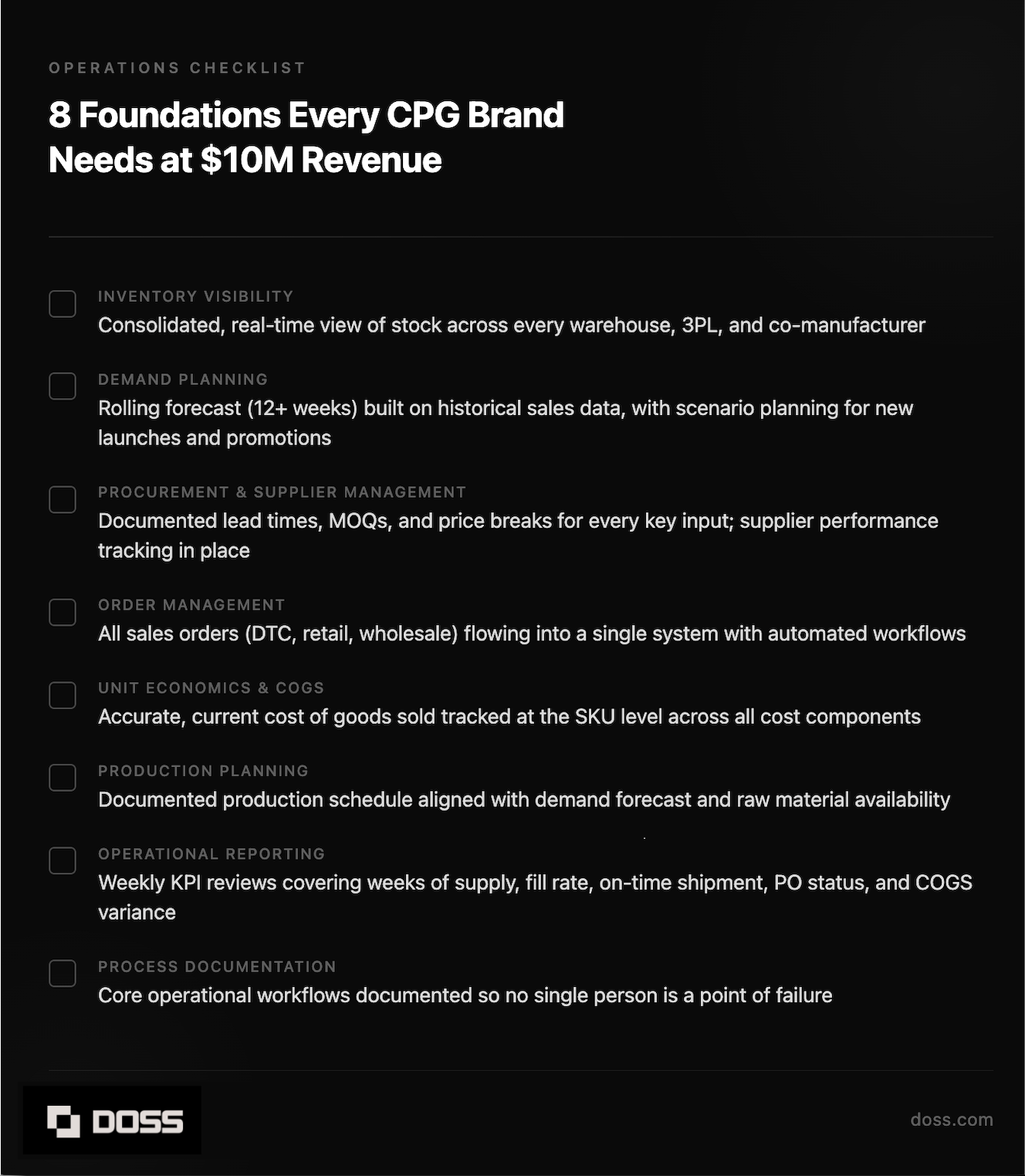

The Checklist

1. Establish End-to-End Inventory Visibility

At $10M, you're likely selling through multiple channels: DTC , Amazon, a growing roster of retail accounts, maybe a distributor or two. Inventory is probably sitting in more than one warehouse, and you may have raw materials at a co-manufacturer as well. The first operational priority is simple to describe and notoriously hard to execute: know what you have, where it is, and where it's going.

This means consolidating inventory data from every warehouse, 3PL, and co-manufacturer into a single, real-time view. You need to be able to answer basic questions without digging through three different portals. How many units of a given SKU are available to sell right now? How many are in transit? How many are allocated to open orders? If answering those questions takes more than sixty seconds, you have a visibility problem.

At this stage, you should also be tracking inventory by lot or batch, especially if you have products with expiration dates. FIFO (first in, first out) compliance becomes critical when you're managing real volume, and a single expired-product incident at a retail partner can damage a relationship that took months to build.

2. Build a Demand Planning Foundation

Demand planning doesn't need to be sophisticated at $10M, but it does need to exist. Too many brands at this stage are still ordering based on what they think they'll need rather than building projections grounded in actual data.

Start with what you know: historical sales velocity by SKU and by channel. Layer in known upcoming events like new retail launches, planned promotions, and seasonal trends. Then create a rolling forecast that extends at least 12 weeks out, ideally further if your production lead times are long. The goal isn't to be perfectly accurate. It's to have a shared, documented view of expected demand that your operations, sales, and finance teams are all working from.

For brands without long track records of durable demand (maybe you're launching with a new major retailer or running one-time promotions) scenario planning becomes essential. Build upper and lower bounds for your projections and think through the operational implications of each. What happens if you sell 2x what you expect? What if you sell half? Having contingency plans for both scenarios is far more valuable than pretending you can nail a single-point forecast.

3. Formalize Your Procurement and Supplier Management

At $10M, supplier relationships become a real operational lever. You're buying enough volume that lead times, pricing, and quality consistency all have meaningful financial impact. Yet many brands at this stage are still managing procurement through email threads and informal commitments.

This is the time to formalize. Document your lead times for every key ingredient and packaging component. Know your minimum order quantities and price breaks. Track supplier performance, not just whether they delivered, but whether they delivered on time, in full, and to spec. Build a simple scorecard if nothing else.

You should also be thinking about supply risk. If a single supplier provides a critical ingredient and they go down for two weeks, what happens to your production schedule? At $10M, you should have backup suppliers identified for your highest-risk inputs, even if you haven't fully qualified them yet. The time to find a backup is before you need one.

4. Get Your Order Management Under Control

Growing brands often reach $10M with order management processes held together with duct tape. Retail EDI orders flow into one system, DTC orders into another, wholesale orders come in via email, and someone on the team is manually reconciling everything.

The checklist item here is straightforward: every sales order, regardless of channel, should flow into a single system of record. From there, you should have clear workflows for order confirmation, allocation, pick-and-pack, shipment, and invoicing. Automating as much of this as possible isn't a luxury at $10M. It's a necessity. Manual order processing is slow, error-prone, and impossible to scale.

Pay particular attention to your retail compliance. Big retailers enforce strict routing guides, labeling requirements, and delivery windows. Chargebacks for non-compliance add up fast and eat directly into your margins. Make sure your ops team understands each retailer's specific requirements and that your fulfillment process is configured to meet them consistently.

5. Nail Your Unit Economics and COGS Tracking

You cannot scale profitably if you don't have a clear, current picture of your cost of goods sold at the SKU level. At $10M, your COGS structure is complex enough that estimates and approximations will mislead you. You need to track actual ingredient costs, packaging costs, co-manufacturing fees, inbound freight, warehousing, and fulfillment. And you need those numbers updated regularly, not just once a quarter.

This matters for more than just financial reporting. Accurate COGS data informs which products to promote, which channels are actually profitable after trade spend and fulfillment costs, and where you should focus operational improvement efforts. Brands that run on rough margin estimates at $10M inevitably discover that some of their "best sellers" are barely breaking even once all costs are allocated properly.

6. Implement Production Planning Discipline

If you're working with co-manufacturers, production planning at $10M means more than calling your co-manufacturer and placing an order. You should have a documented production schedule that's informed by your demand forecast and aligned with your raw material availability. You need to know your production lead times, minimum run sizes, and the cadence at which you're placing production orders.

The coordination between procurement, inventory, and production is where many brands struggle most. A late ingredient shipment delays a production run, which delays a retail delivery, which triggers a chargeback. These cascading failures are preventable, but only if you have the visibility and planning processes to see problems before they become crises.

7. Build Reporting That Drives Decisions

At $10M, you should have a set of operational KPIs that you review weekly. Not monthly, not "when we get around to it." Weekly. At a minimum, this should include inventory weeks of supply by SKU, fill rate by channel, on-time shipment rate, open purchase order status, and COGS variance to plan.

The challenge for most brands at this stage isn't knowing which metrics matter. It's getting the data into a format that's actually usable. When your information lives across a dozen different platforms (your 3PL portal, your Shopify backend, your accounting software, your co-manufacturer's spreadsheets), building a coherent operational picture requires either significant manual effort or a platform that can pull it all together.

8. Document Your Processes

This one is easy to deprioritize and expensive to ignore. At $10M, you likely have a small but growing ops team, and much of the institutional knowledge about how things work lives in one or two people's heads. If your ops lead takes a two-week vacation, can someone else place a production order, process a retail PO, or reconcile inventory?

Document your core operational workflows. It doesn't have to be elaborate. A shared document for each key process with the steps, the tools involved, and the decision points is enough. This becomes the foundation for training new hires, identifying bottlenecks, and eventually automating repetitive tasks.

How DOSS Can Help

Most of the items on this checklist share a common root challenge: data is scattered across too many systems, and the team is spending too much time wrangling information instead of acting on it.

That's the problem DOSS was built to solve. DOSS Operations Cloud is an adaptive resource platform designed specifically for growing consumer goods brands. It's for companies that have outgrown spreadsheets and basic tools but don't need a traditional enterprise ERP implementation.

DOSS unifies inventory, orders, procurement, and production planning into a single system, giving your team a real-time, consolidated view of operations across every warehouse, 3PL, and sales channel. With over 30 prebuilt integrations, DOSS connects to the tools you're already using (your POS systems, your 3PLs, your co-manufacturers) and automatically synchronizes data so you're always working from one source of truth.

Unlike legacy ERP systems that force you to redesign your business processes around rigid software, DOSS adapts to how your business actually works. And because the platform is built with AI at its core, DOSS doesn't just store your data. It helps you act on it, surfacing insights around demand patterns, reorder timing, and production scheduling that would take hours to uncover manually.

If your brand is at $10M and you recognize the operational gaps described above, it might be time to explore what a purpose-built operations platform can do. You can learn more at doss.com .