At DOSS we are laser-focused on helping our customers manage the flow of goods, dollars, and data into and out of their business. It only makes sense that all of them are leveraging the “Core-3” modules of DOSS ARP:

- Procurement (P2P) : Orders things from vendors / suppliers / manufacturing partners

- Inventory Management (IMS) : Tracking things in 1P warehouses and 3P warehouses

- Order Management (OMS) : Selling things, getting them into customer hands, and sometimes getting them back

Each of these individually in isolation is relatively trivial to implement with consumer productivity tools (i.e. Excel, GSheets) or in a lightweight ERP. But as a business scales up (more vendors, more warehouses, more products, more channels!) so does the surface area of interactions between these concepts–and consequently the complexity! This is where the wheels really start to come off.

A few examples: sales pre-orders when SKUs are out of stock, multi-currency FX handling in 3-way matching on procurement, omni-channel orders with varied AR workflows, mixed 1P WHs and 3PL WHs, and so much more.

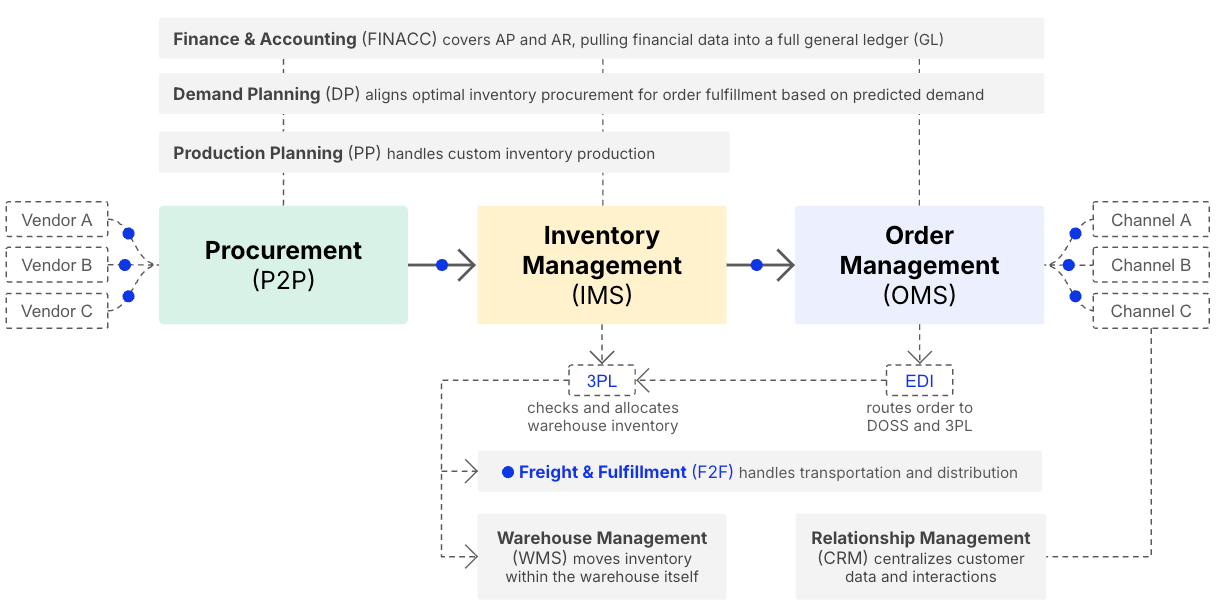

All of the other advanced functionality we offer (i.e. Demand Planning, MES/Production Planning, Freight and Fulfillment) rely on the data model and workflows of the Core-3 being connected seamlessly.

What’s more, the real power emerges as you connect each together, enabling end-to-end automation where previously processes would get delayed, bottlenecked, or stopped dead in their tracks completely.

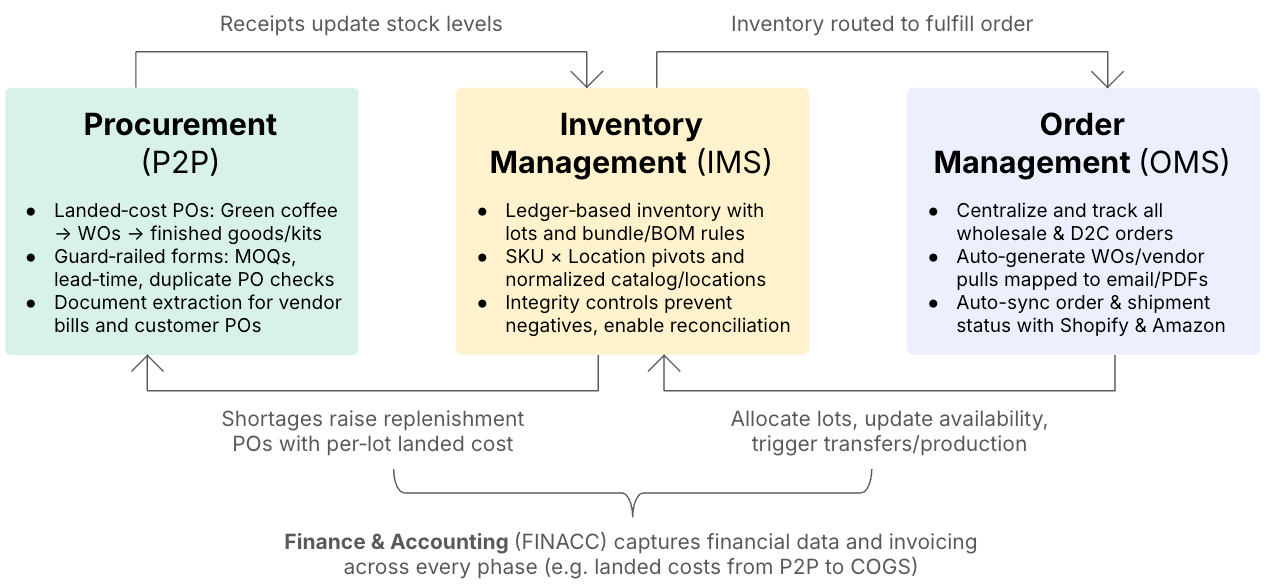

How P2P, IMS, and OMS work together

The value chain for most companies is about information flowing through the Core-3 modules. Imagine receiving a large customer order: the order gets captured and verified, inventory levels update in real time to reflect the sale, and if stock runs low, procurement automatically kicks in to source replenishment from suppliers.

When these systems operate in isolation, gaps appear: orders get delayed, inventory becomes inaccurate, and procurement becomes reactive rather than strategic. But when integrated, they create a seamless flow of information that enables smarter decisions, faster response times, and healthier margins.

For example, Kahawa 1893 , a specialty coffee company, achieved 30x faster order processing by fully integrating and automating processes with DOSS. Here’s how Kahawa coordinates operations across P2P, IMS, and OMS modules:

Variations across business types

The implementation and focus across these core systems varies a lot based on your business model, as well as who owns the overall work product system (a.k.a VAP, “value-added product” / “value-added processing”), and the level of technical resources available internally.

1. Fast-moving vs. slow-moving inventory: low vs. high AOV/ASP

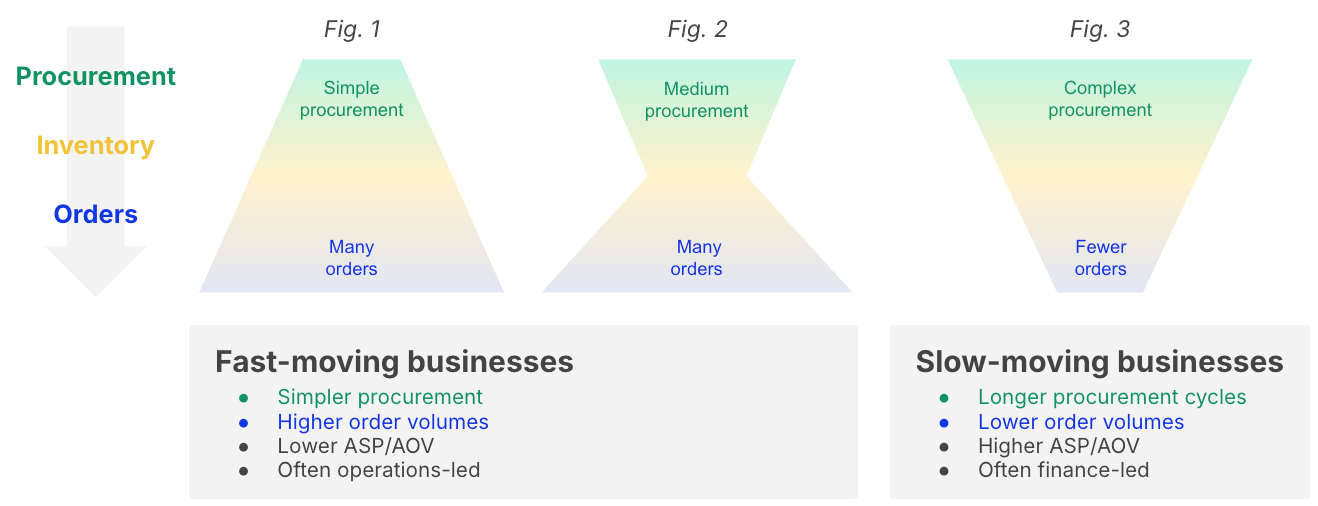

There are three common shapes for every business. The majority tend to fall into the first two fast-moving categories with simpler procurement and a wider volume of orders:

Fast-moving businesses (e.g. e-commerce, food & beverage) need real-time inventory tracking, automated reorder points, and streamlined order processing (Figure 1). They process high volumes of orders that are typically fulfilled within days, often with lower ASP and AOV (aka average selling price and average order volume, respectively). Depending on business complexity, procurement may involve a slightly wider funnel of incoming parts and suppliers to fulfill a wider variety of product lines and SKUs (Figure 2).

Slow-moving businesses (e.g. manufacturing, B2B) have much longer procurement cycles and more complicated production processes (Figure 3). They’ll spend more time managing procurement and inventory transformation to produce the end product. These businesses tend to have higher ASP and AOV, with fewer but more valuable transactions requiring detailed tracking and personalized fulfillment processes.

2. Ownership of work product (VAP)

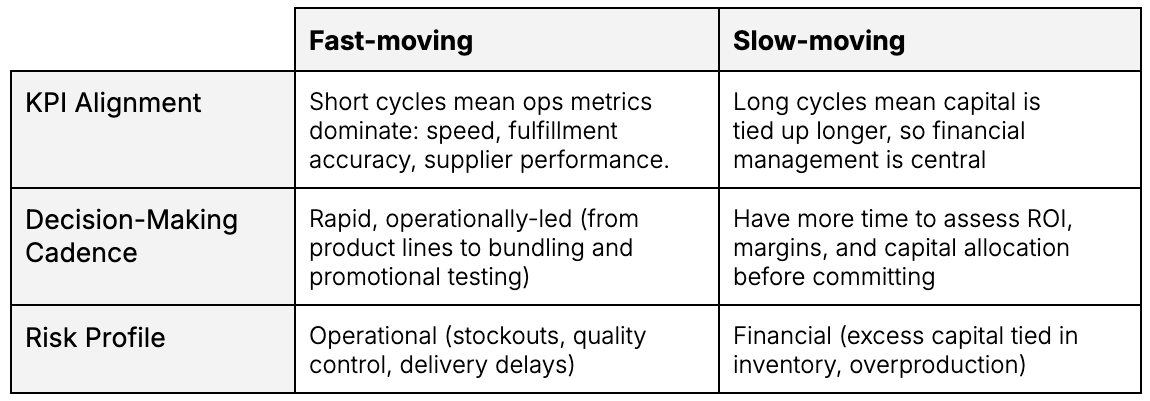

Who owns the overall operational system makes a big difference on the key performance indicators (KPIs) that matter, as well as how that business optimizes its operations.

Operations-led businesses are typically owned by the COO or VP/Director of Ops. They care about OTIF (On Time In Full), cycle times, inventory turnover, supplier performance, customer satisfaction scores, and process efficiency metrics to optimize operational health and service.

Finance-led operations are typically owned by the CFO or CRO. They care about profit margins, working capital efficiency, cost per unit, budget variance, cash conversion cycles, and ROI on inventory investments. Financial performance and cost control is key at every stage.

This ownership distinction shapes everything from which alerts get priority attention to how success is measured and communicated to stakeholders. An operations-led business might optimize for faster fulfillment times, while a finance-led operation might prioritize inventory reduction even if it means slightly longer lead times.

Unsurprisingly, there’s also a loose correlation between fast-moving + operations-led vs. slow-moving + finance-led businesses. To expand that comparison:

While these patterns are common, exceptions abound: A slow-moving business might be operations-led if it’s in a highly service-dependent industry (e.g. custom aerospace), while a fast-moving business may be finance-led if operating in thin-margin sectors (e.g. discount retail).

3. Technology native: build vs. buy

Lastly, company culture tends to influence how businesses build operational systems from startup to enterprise. Technology-native companies often build custom software solutions to manage their operations, leveraging in-house engineering teams to create tailored workflows. In contrast, traditional companies typically start with productivity tools like spreadsheets and basic software before eventually considering established ERP solutions.

The initial approach really comes down to available resources—companies with engineers and technical analysts naturally gravitate toward custom-built solutions. This can work well in early stages when operations are simple and the team is small enough to maintain custom code.

However, as companies scale, homebaked systems typically become unsustainable due to maintenance burden, integration complexity, security, and efficiency concerns. This is where DOSS ARP comes in: our fully composable platform adapts to your exact processes, designed for enterprise-grade complexity and automation without the rigidity or lag of traditional ERPs.

Managing P2P, IMS, and OMS with DOSS

When we onboard a new DOSS customer, we start with a simple but powerful question: How do orders, inventory, and procurement follow the flow of goods and money in your business today, and how should they work in the future?

That conversation shapes how we configure P2P, IMS, and OMS for their specific needs. It also reveals which supporting modules—like demand planning, warehouse management, or CRM—will help close gaps, automate repetitive work, and give their teams more time to focus on strategic growth. Below is a broad visualization of how these additional modules may map around P2P, IMS, and OMS. In practice, most customers will use a subset of these capabilities:

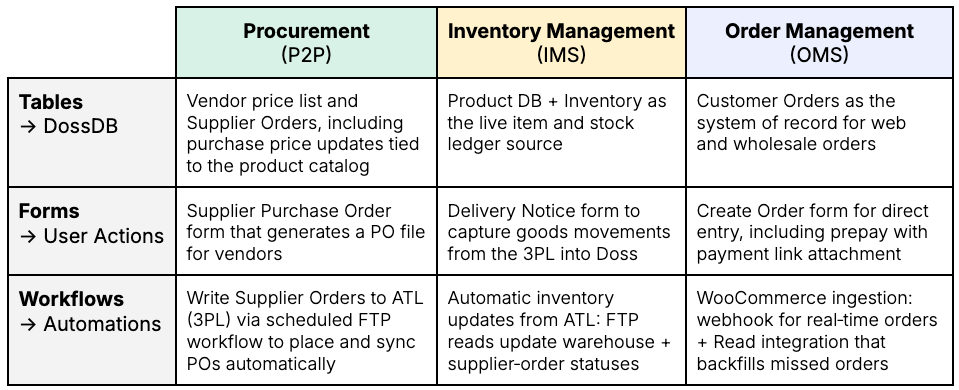

Each module is then customized with tables that provide a live system of record, forms to capture and initiate tasks, and workflows to automate everything in between. While each module typically includes many workflows plus several forms and tables, here are a few specific examples used by Noodles , a furniture company that saves 100+ hours per month with DOSS:

Conclusion

For most businesses, P2P, IMS, and OMS are the beating heart of operations. But without integration, they often create more complexity than clarity. At DOSS, we unite these systems into a single connected platform, ensuring data flows freely and processes run without friction.

The result is a foundation that’s not just operationally sound, but strategically powerful—helping businesses adapt faster, make better decisions, and scale with confidence.